I have to admit my frustration with our culture’s sense of disposability when it comes to our built environment. I hate to think about the cubic tonnage of discarded building material that has gone out of vogue.

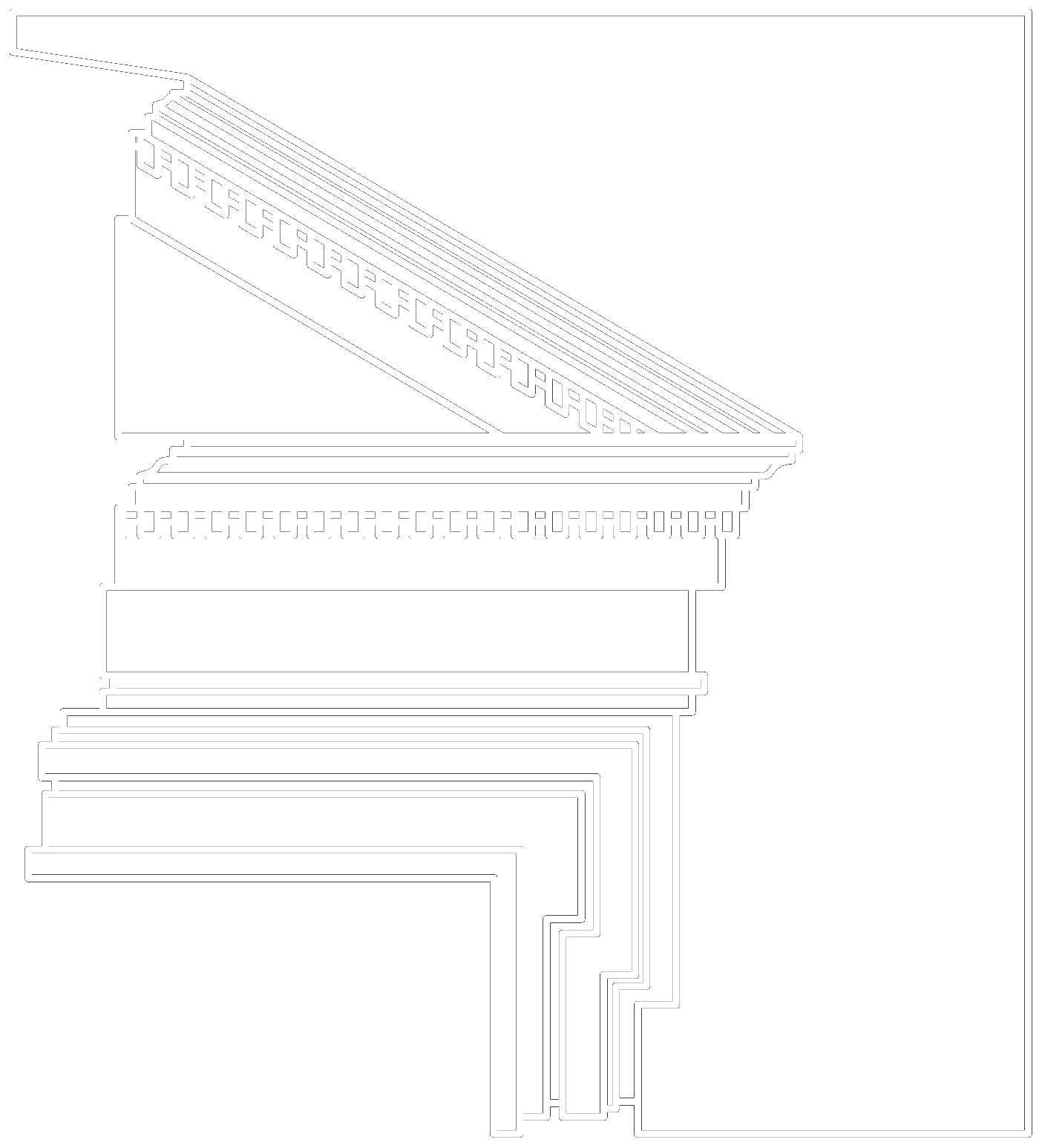

Live Edge of Danby Imperial Marble

Square miles of stone countertops and flooring have been replaced in the past decade alone! Selecting and specifying materials is a big part of my job. It is something that I take very seriously, especially when it is considered in the context of sustainability.

I recently went on a slab-selection trip at the Vermont Quarries facility in Danby, VT. It was an awe-inspiring experience. This quarry has been in operation for over 100 years, providing the marble for such esteemed buildings as the Lincoln Memorial, the White House, the Shanghai Temple and the New York Public Library. Additionally, it is the source for the pure white stone used in the National Cemetery.

New York Public Library

Entry to the Danby Quarry

We arrived at the quarry at 9:30 on a Tuesday morning. If you didn’t know where you were, you would never believe that behind the garage door in the side of a mountain, there was a cavern that continues for a mile and a half! Upon arrival, we were fitted up with hard hats and oxygen devices in the “unlikely event of an emergency”.

The space inside this mountain belittles that of Saint Paul’s Cathedral. Driving through the enormous vaulted chambers, I felt of Lilliputian scale. Enormous blocks of marble lined the passages everywhere you looked, and a whole network of transporting machinery has been inserted in the mountain like some sort of skeletal structure.

Inside the Quarry

Wetting the slab to determine the colour of the finished product.

Our tour guide, Mike, the quarry manager, was a wealth of knowledge, and very helpful in locating the type of slab we were looking for. It is very important to wet-down the stone you are viewing to reveal what the true colour is. (We looked at one slab that surprised us with a green hue when soaked.)

The stone’s color and pattern is the result of both its geological makeup and how it is cut. The cut of the stone also effects the durability of the material. Two of the most common cuts are “flurry cut” and “vein cut”. In vein cut stone, the material is cut perpendicular to the natural layers of the metamorphic process. This reveals the striation of the individually articulated strata. Flurry stone is cut parallel to the strata, exposing a more random veining. Because of the inconsistency of the stratas’ densities, vein cut stone is considered more brittle and often requires epoxy & fiberglass reinforcement. However, its’ dramatic patterning makes it ideal for book-matching.

No matter what your application, it is important to consider natural stone as a truly precious and limited resource.